Optimize Your 3D Printing Post-Processing Workflow with Precision Cleaning & Curing

Improve quality, reduce remakes, and speed up post-processing production with advanced wash and cure units designed specifically for 3D printing in dental labs. The post-processing of your 3D printed parts is a vital part of any lab’s digital workflow and without the right equipment your lab might be sacrificing esthetics and consistency that may result in remakes.

The washing units and curing units available from Zahn Dental can be implemented into your digital production process with ease. We offer solutions from leading suppliers like Asiga, Desktop Health, Formlabs, Kulzer, and more—so you can count on performance, reliability, and long-term scalability.

Ackuretta

Optimize 3D printing with Ackuretta CURIE, CURIE Plus & CLEANI. Automate resin washing & UV curing for stronger, biocompatible, and high-quality dental applications.

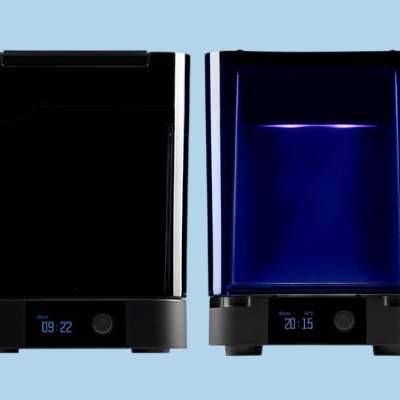

Asiga

Automate post-processing with Asiga Wash & Cure Units. Get faster, stronger 3D prints with vacuum curing, infrared heating, and smart resin compatibility.

Desktop Health

Automate 3D post-processing with Desktop Health Wash & Cure Units. Get stronger, flawless dental models with hands-free resin washing & high-intensity UV curing.

Dreve

Enhance 3D print durability with the Dreve PCU LED N2. Get flawless curing with vacuum-sealed, nitrogen-assisted polymerization for stronger, high-quality parts.

Formlabs

Automate 3D print post-processing with Formlabs Wash & Cure Units. Get cleaner, stronger prints with hands-free resin removal and precision LED heat curing.

Kulzer

Automate dental 3D post-processing with Kulzer cara® Wash & Cure Units. Achieve cleaner, stronger restorations with hands-free washing & advanced LED curing.

Onulis

The WRAP® Pro by Onulis transforms unused UV resin into safe, disposable plastic for dental labs. Eliminate hazardous waste costs & EPA concerns. Learn more!

Why Wash and Cure Units Are Essential for Dental Labs

The post-processing stage in the 3D printing workflow is just as important as the printing stage. Dental labs rely on wash and cure systems to:

- Remove residual 3D print resin from models and appliances

- Harden prints evenly with consistent light exposure

- Strengthen final parts for long-term use

- Maintain the integrity and detail of every print

What Features Should I Look for in a Wash and Cure Unit?

How Do I Maintain My Wash and Cure Unit?

- Clean the chamber and exterior regularly.

- Monitor and replace IPA as needed.

- Inspect and clean the tank to remove resin residue.

- Calibrate temperature and timers for accurate performance.

How Long Should I Wash and Cure Resin Prints?

Curing: Generally 2-5 minutes at 40-50°C, depending on resin type.

What Are the Safety Guidelines for Using Wash and Cure Units?

- Operate in a well-ventilated area to reduce IPA fumes.

- Wear gloves, safety glasses, and a lab coat for protection.

- Keep units away from heat sources and open flames.

- Dispose of used IPA and resin waste properly according to regulations.

How Can I Maximize Efficiency in My Lab?

- Batch process multiple prints for higher productivity.

- Use automatic cycle features and remote monitoring.

- Update software regularly to maintain peak performance.

- Keep machines clean and well-maintained to prevent downtime.

Find the Right Wash & Cure System for Your Dental Lab

Our Dental Lab Wash and Cure Units are designed for labs that demand speed, precision, and reliability. Whether you need automated resin washing, UV curing, or a full post-processing system, we have the solution to help you work faster, smarter, and more efficiently.